Exploring the Efficiency of Electrically Actuated Butterfly Valves in Process Control

As the field of process control continues to grow, it becomes increasingly important to manage the flow, and functionality as well as achieve maximum efficiency. The electrically actuated butterfly valve is one of the reigning valves in process control owing to its reliability, efficiency, and energy sparsity. This write-up investigates the inaudible workings, benefits, and even areas of electrically actuated butterfly valves that concern process control systems. Effective use of operational processes through these valves translates into better business performance, improved energy efficiency, and increased sustainability in the long run. In addition, lowering the cost of operation and improving safety in automated systems is made possible with the use of these valves.

Explaining the Electric Water Valve

As the name suggests, electric water valves are ‘silent sentries’ that the user does not have to be physically present to open or shut. The sensor on the valve will take care of that. They are preferred over manual valves because electric water valves have a high level of precision, are easily incorporated into control process systems, increase overall efficacy, and most importantly, reduce the requirement for human operators. In short, accessible modes of control and little wear to the actual machinery makes coverage and usage in potentially hazardous areas automatic and seamless. Commencing reverberating water purification and chemical managing industries all the way to food enterprise, electric water valves are extremely vital for these industries. Furthermore, they are able to be integrated with equally advanced automation systems which allow valves to respond quicker and be in a constant state of availability while greatly reducing the chances of the system being disrupted. As a result, there is no wastage of resources.

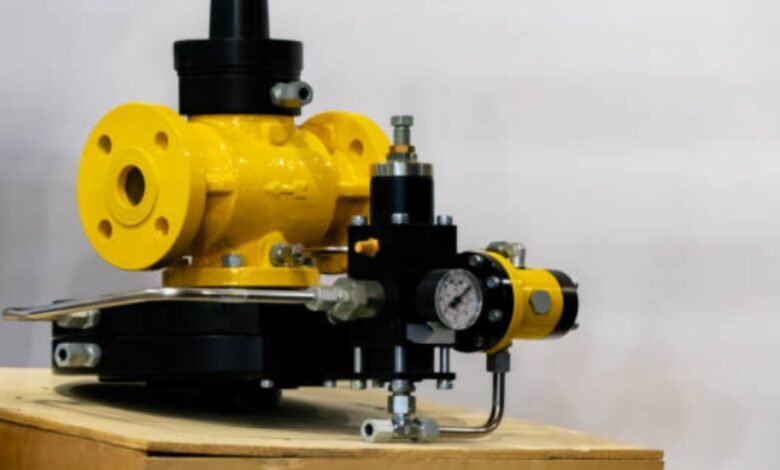

The Function of Butterfly Valves with Electric Actuators in Process Controlling

The use of electrically actuated butterfly valves is so common in process control applications because they can efficiently control the fluid flow. The electric actuator moves the valve according to signals from the control system. Electric butterfly valves are capable of maintaining the desired flow rate and pressure for automatic control systems in water treatment plants, chemical manufacturing facilities and food processing industries. With the integration of electronically controlled butterfly valves into automated control systems, remote control of operating systems becomes possible, which greatly facilitates the work of personnel. This is also done to increase efficiency. In addition to that, these valves provide the ability to remotely control the processes of pouring liquids, gasses or steam while significantly decreasing the need for human labor. This system configuration allows reducing operational errors which improves the output’s quality and consistency. The industrial valves can be used singularly or in a series due to their compatibility with different types of flexible piping systems. In these days where massive amounts of fluid should be transmitted with high speed, lowering the cost and increasing the efficiency of the piping system, electric actuated butterfly valves are definitely the most useful option.

Benefits Of Butterfly Valves With Electric Actuators

Butterfly valves with electric actuators have importance including but not limited to advanced features. For instance, their energy use is very low. High energy is consumed by hydraulic and pneumatic motors. Electric helps trim these costs. More importantly, the precise control the motor gives ensures that the system never spends excessive energy and the flow rate is never wasted. Lastly, one of the most important coons of electric butterfly valves is high rate of elastomeric and polymeric corrosion resistance. Most electric butterfly actuators are designed to take high pressure and temperature environments. Electric motors often have very few moving parts leading to the actuator wearing down less so they will have very little maintenance requirements. These valves are easy to use as they can be integrated into other systems easily. Moreover, these valves are compatible with some polymeric materials that are best suited for high speed flow control which can only be found in some industries. Along with that, they can also be housed in tighter spots as compared to bigger valves. Because of their small size, they can be used more widely as compared to standard valves. As a result, operations affected by maintenance are reduced therefore improving efficiency.

Uses of Electric Water Valves in Industry

Electric water valves are versatile and reliable and as such, they find use in various processes in different industries. In water treatment facilities, these valves are important for controlling water circulation during the treatment process to guarantee effective filtration and removal of water impurities. In the chemical industry, electrically actuated butterfly valves can be used in processes involving aggressive chemicals and extreme temperatures because they are reliable for fluid flow regulation to complex processes. The food and beverage industry also benefits from these valves as they maintain hygienic conditions while controlling the flow of ingredients or liquids during production. In addition, these valves are also used in HVAC systems, energy generation plants, and pharmaceutical manufacturing, which further extend their applicability in diverse regions. These industries depend on the valves for consistent and reliable flow control. Electric water valves gain prominence in modern industrial systems due to their ability to function under varying extreme conditions and with a wide range of fluids. To add on, these valves help mitigate energy consumption and waste in industries and therefore support sustainability efforts.

Identifying an Electric Valve Manufacturer

Choosing the right manufacturer is vital while searching for the best electrically actuated butterfly valves. Electric ball valve manufacturers in China, for example, are reputable for the technologically advanced valves that they supply which exceed international requirements on standards and performance. Collaboration with reputable manufacturers guarantees durable, efficient, and affordable products that are designed specifically for the customer’s needs. They also offer important technical advice when it comes to valve selection, installation, and maintenance which helps in running the system effectively. When adequate and efficient steps are taken, the benefits and value of electrically actuated butterfly valves can be fully realized for improved efficiency in the process control system. Furthermore, the broad scope of experience that these manufacturers bring can ensure a low price and fast business, so that there is no restriction to new discoveries and advancements in the field of valve automation.

Electric actuated butterfly valves are indispensable elements for contemporary process control systems. Their energy efficiency, long service life, and ease of integration make them suitable for industries such as mining, oil and gas, and manufacturing which require flow control at a higher level. Whether it is serving the food industry, chemical industry, or the waterworks sector, they provide a dependable solution that increases production and minimizes costs. With the correct selection of a distributor, the efficiency, sustainability, and cost savings of the systems can be maintained in the long run. The shift of industries toward greater complexity and interdependence will place a premium on efficiency, automation, and electric actuated butterfly valves for control in process control systems.

2 Comments